Definition and Basic Concept of Hexagonal Rivet Nuts Hexagonal rivet nuts are internally threaded fasteners designed to create strong, load-bearing threads in thin or hollow materials where convention...

READ MOREThe company has obtained two quality system management certificates of ISO9001:2015 and IATF16949:2016.

At present, the company has been for Japan, Sweden, the United States, Singapore, Malaysia, Hong Kong and the Pearl River Delta and many other customers to provide services, now the main customers are: Japan Sharp (SHARP), Japan SMC, Japan Panasonic (Panasonic), the Swedish automobile VOVOL, etc., all the fixed assets investment of more than 30 million dollars, welcome friends from all walks of life to the factory to visit, study, consulting and come! We welcome friends from all walks of life to visit our factory, investigate, consult and come to us for sample processing.

We are looking forward to establishing a good business partnership with you with mutual trust and reciprocity!

-

-

Understanding Sealing Requirements in Hydraulic and Pneumatic Systems Hydraulic and pneumatic connections operate under internal pressure, media flow, and frequent pressure fluctuations. In these syst...

READ MORE -

Introduction to Screw Hardware Screw hardware is a fundamental component in construction, manufacturing, and DIY projects. It plays a critical role in joining materials securely, providing structural ...

READ MORE -

Introduction to Round Head Cross Bolts Round head cross bolts are a type of fastener widely used in construction, machinery, and industrial applications. They feature a rounded head with a cross slot ...

READ MORE

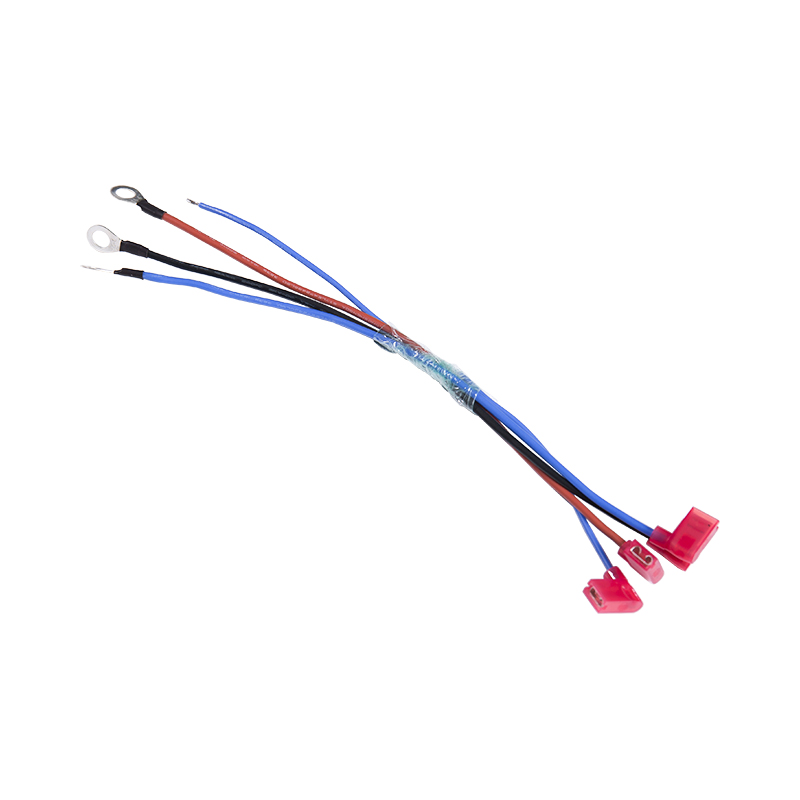

How do wiring harness injection moulded parts protect wires?

The ways in which wiring harness injection moulded parts protect wires are mainly reflected in the following aspects:

Fixing Wires: wiring harness injection moulded parts are designed with specific grooves or channels to precisely fix the positions of wires and cables. This fixation prevents wires from shifting or tangling inside the equipment due to vibration, impact, or daily use. Some molded parts are also designed with locking mechanisms, such as clips or adhesives, to ensure that the wires remain fixed during long-term use.

Preventing Physical Damage: The outer casing of the injection molded parts provides a physical barrier that protects wires from external impacts and pressure. This is particularly important for equipment used in harsh environments, such as automobiles, industrial machinery, or outdoor equipment. The thickness and strength of the casing can be customized based on the wire's diameter and the required level of protection.

Isolating Environmental Factors: wiring harness injection moulded parts can be designed as sealed structures to prevent moisture, dust, and other contaminants from entering. This is crucial for improving the reliability of the equipment and extending maintenance intervals. Some molded parts also feature waterproof and dustproof functions, meeting specific protection levels (such as IP ratings).

Preventing Chemical Erosion: Choosing materials resistant to chemical corrosion, such as Polyamide (PA) or Polybutylene Terephthalate (PBT), can protect wires from chemical damage, especially in chemical plants or laboratory environments. These materials can resist various chemicals, including acids, bases, and solvents.

Providing Mechanical Support: wiring harness injection moulded parts not only protect wires but also serve as mechanical support points for the entire electronic system. They can be designed to withstand tension, pressure, and other mechanical loads, thereby protecting the wires from excessive stress. During the design process, the layout of the wires and the working conditions of the equipment are considered to ensure that the molded parts can provide sufficient support.

Organizing Wire Layout: wiring harness injection moulded parts help maintain an orderly layout of the wires, reducing mutual interference, such as electromagnetic interference (EMI) or radio frequency interference (RFI). This is crucial for ensuring clear signal transmission and the performance of the equipment. An orderly layout also helps simplify the assembly process and improve production efficiency.

Adapting to Temperature Changes: The material selection for wiring harness injection moulded parts can take into account the impact of temperature changes. For example, using thermoplastic materials can maintain their performance over a wide temperature range, protecting wires from thermal expansion and contraction. In extreme temperature environments, such as high or low temperatures, the design of the molded parts needs to consider the material's temperature resistance.

Sealing Performance: For equipment that requires waterproof or dustproof protection, wiring harness injection moulded parts can be designed with sealed edges or covers to prevent liquids and particles from entering. High-quality sealing performance is crucial for protecting sensitive electronic components and extending the equipment's lifespan.

Through these detailed protective measures, wiring harness injection moulded parts ensure the safety and reliability of wires and cables under various conditions, thereby enhancing the performance and lifespan of the entire electronic equipment.

русский

русский Español

Español