Definition and Basic Concept of Hexagonal Rivet Nuts Hexagonal rivet nuts are internally threaded fasteners designed to create strong, load-bearing threads in thin or hollow materials where convention...

READ MOREThe company has obtained two quality system management certificates of ISO9001:2015 and IATF16949:2016.

At present, the company has been for Japan, Sweden, the United States, Singapore, Malaysia, Hong Kong and the Pearl River Delta and many other customers to provide services, now the main customers are: Japan Sharp (SHARP), Japan SMC, Japan Panasonic (Panasonic), the Swedish automobile VOVOL, etc., all the fixed assets investment of more than 30 million dollars, welcome friends from all walks of life to the factory to visit, study, consulting and come! We welcome friends from all walks of life to visit our factory, investigate, consult and come to us for sample processing.

We are looking forward to establishing a good business partnership with you with mutual trust and reciprocity!

-

-

Understanding Sealing Requirements in Hydraulic and Pneumatic Systems Hydraulic and pneumatic connections operate under internal pressure, media flow, and frequent pressure fluctuations. In these syst...

READ MORE -

Introduction to Screw Hardware Screw hardware is a fundamental component in construction, manufacturing, and DIY projects. It plays a critical role in joining materials securely, providing structural ...

READ MORE -

Introduction to Round Head Cross Bolts Round head cross bolts are a type of fastener widely used in construction, machinery, and industrial applications. They feature a rounded head with a cross slot ...

READ MORE

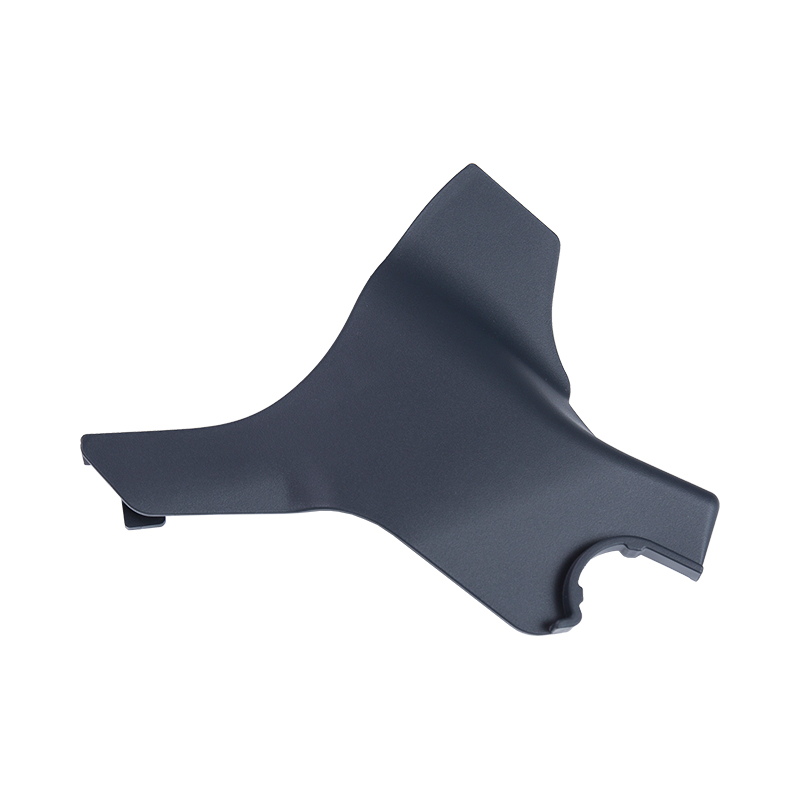

Which plastic materials are best for automotive injection molded parts?

In the application of automotive injection molded parts, selecting the appropriate plastic material is usually based on a range of factors, including mechanical properties, heat resistance, chemical resistance, processing performance, cost-effectiveness, and aesthetics. Here are several plastic materials widely considered suitable for automotive injection molded parts:

Polypropylene (PP): PP is widely used in automotive injection molded parts due to its lightweight, cost-effectiveness, good chemical resistance, and excellent processing performance. It can be used to manufacture interior parts such as dashboards, door panels, air ducts, and fans, as well as some under-the-hood components. To improve PP’s heat resistance and rigidity, it is often modified with fillers or copolymers, such as talc or glass fibers.

ABS Resin: ABS resin is known for its excellent mechanical properties (such as high strength and good impact resistance) and processing performance. It is commonly used to manufacture automotive body panels, headlamp housings, wheel covers, dashboard trim, and interior decorative strips. Additionally, ABS can be blended with other materials like PVC and PC to achieve better performance through alloying techniques.

Polycarbonate (PC): PC is an ideal choice for automotive lighting systems (such as transparent covers for taillights and headlights) due to its high transparency, impact resistance, and heat resistance. PC can also be used to manufacture interior decorative parts that require high transparency and impact resistance.

PC/ABS Blends: This blend combines the impact resistance of PC and the processing performance of ABS, offering excellent surface appearance and mechanical properties. It is often used to manufacture automotive dashboards, consoles, trim strips, and some high-appearance interior and exterior parts.

Polyamide (PA): PA, especially reinforced PA such as glass fiber-reinforced PA66, is suitable for manufacturing high-temperature and mechanically stressed components in the engine compartment, such as intake manifolds, cooling fans, and engine mounts, due to its high strength, heat resistance, and chemical resistance.

Polyoxymethylene (POM): POM has excellent wear resistance, rigidity, and chemical stability, making it suitable for manufacturing moving parts in cars, such as gears, bearings, and door lock components. Its low friction coefficient also makes it ideal for sliding applications.

Polyvinyl Chloride (PVC): PVC has good flexibility, cost-effectiveness, and ease of processing, and is commonly used to manufacture automotive seals, cable sheaths, and hoses. Its flexibility and the ability to be adjusted with plasticizers make it suitable for specific applications in automotive injection molded parts.

Polybutylene Terephthalate (PBT): PBT is favored for its heat resistance, chemical resistance, and electrical insulation properties, making it commonly used to manufacture electrical components such as ignition system parts, sensors, and connectors. PBT can also be used to make some structural parts in high-temperature environments.

Thermoplastic Elastomers (TPE/TPR): TPE/TPR are used for making automotive handles, seals, and gaskets due to their softness and elasticity. They provide a good tactile feel and cushioning performance and can bond with various plastic materials, facilitating composite molding.

The choice of material depends on the specific requirements of the automotive injection molded parts, including performance, cost, processing methods, and environmental impact. As technology advances and new materials are introduced, the applications and performance of these materials continue to expand and improve.

русский

русский Español

Español