Definition and Basic Concept of Hexagonal Rivet Nuts Hexagonal rivet nuts are internally threaded fasteners designed to create strong, load-bearing threads in thin or hollow materials where convention...

READ MOREThe company has obtained two quality system management certificates of ISO9001:2015 and IATF16949:2016.

At present, the company has been for Japan, Sweden, the United States, Singapore, Malaysia, Hong Kong and the Pearl River Delta and many other customers to provide services, now the main customers are: Japan Sharp (SHARP), Japan SMC, Japan Panasonic (Panasonic), the Swedish automobile VOVOL, etc., all the fixed assets investment of more than 30 million dollars, welcome friends from all walks of life to the factory to visit, study, consulting and come! We welcome friends from all walks of life to visit our factory, investigate, consult and come to us for sample processing.

We are looking forward to establishing a good business partnership with you with mutual trust and reciprocity!

-

-

Understanding Sealing Requirements in Hydraulic and Pneumatic Systems Hydraulic and pneumatic connections operate under internal pressure, media flow, and frequent pressure fluctuations. In these syst...

READ MORE -

Introduction to Screw Hardware Screw hardware is a fundamental component in construction, manufacturing, and DIY projects. It plays a critical role in joining materials securely, providing structural ...

READ MORE -

Introduction to Round Head Cross Bolts Round head cross bolts are a type of fastener widely used in construction, machinery, and industrial applications. They feature a rounded head with a cross slot ...

READ MORE

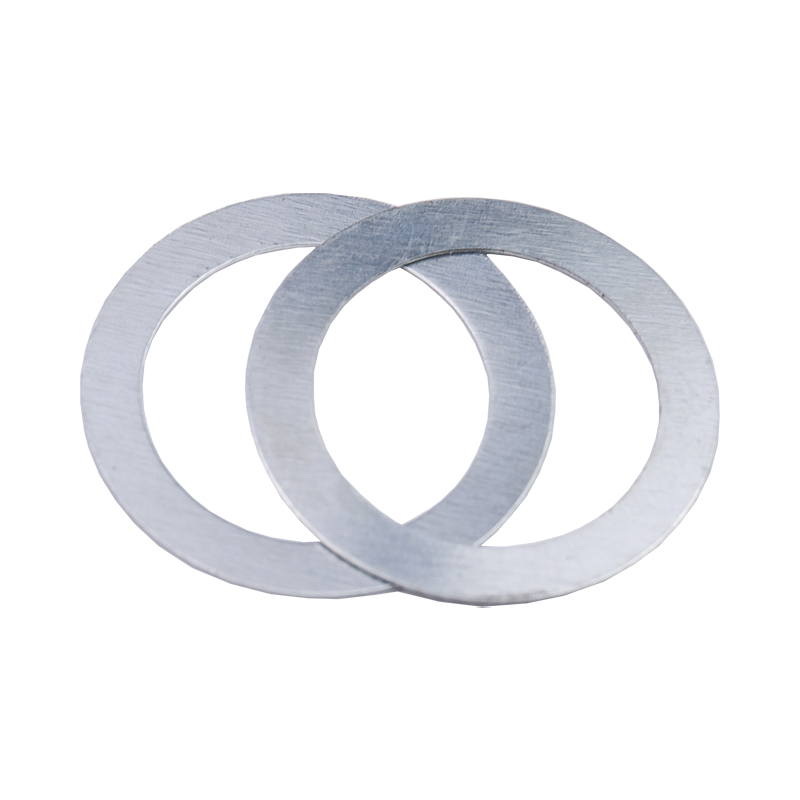

How do non-standard flat washers contribute to optimizing mechanical connections?

Gap Adjustment: Non-standard flat washers can be customized to have specific inner and outer diameters, as well as thicknesses, allowing engineers to precisely adjust the gaps between components. This ensures proper alignment and fit, reducing the risk of misalignment or interference in mechanical assemblies.

Pressure Distribution: By distributing the pressure evenly across the surface of the washer, non-standard flat washers help to prevent localized stress concentrations. This helps to minimize deformation of the mating surfaces and ensures uniform loading of fasteners, contributing to improved stability and longevity of the connection.

Load Balancing: In applications where multiple fasteners are used to secure a joint, non-standard flat washers can be designed to accommodate uneven loading conditions. By distributing the applied load more evenly, these washers help to reduce the risk of overloading individual fasteners and promote uniform clamping force distribution, enhancing the overall integrity of the connection.

Prevention of Loosening: Non-standard flat washers can feature specialized designs, such as serrations or locking features, that provide additional resistance to loosening under vibrational or dynamic loads. These features help to maintain the integrity of the connection over time, reducing the need for frequent maintenance or re-tightening of fasteners.

What are some typical applications of non-standard flat washers in automotive, aerospace, electronics, etc.?

Suspension Systems: Non-standard flat washers are used in suspension systems to adjust the spacing between components, such as control arms and chassis mounts, to ensure proper alignment and handling characteristics.

Engine Assembly: These washers are utilized in engine assembly for tasks such as adjusting valve clearances, spacing engine components, and distributing loads in critical areas.

Body and Chassis: Non-standard flat washers are employed in various body and chassis applications, including securing body panels, reinforcing structural connections, and dampening vibrations.

Aircraft Structures: Non-standard flat washers play a critical role in aircraft structures, where they are used to adjust clearances, distribute loads, and provide secure fastening in components such as wing assemblies, fuselage joints, and landing gear.

Avionics: These washers are used in avionics applications to secure electronic components, provide grounding connections, and isolate sensitive equipment from vibrations and electromagnetic interference.

Propulsion Systems: Non-standard flat washers are employed in propulsion systems for tasks such as securing engine components, adjusting clearance in thrust vectoring mechanisms, and providing thermal insulation.

Printed Circuit Boards (PCBs): Non-standard flat washers are used in PCB assemblies to provide mechanical support, adjust spacing between components, and ensure proper grounding and electrical connections.

Electronic Enclosures: These washers are utilized in electronic enclosures to secure mounting hardware, provide sealing against environmental contaminants, and dissipate heat from high-power components.

Electromechanical Systems: Non-standard flat washers are employed in various electromechanical systems, such as motors, actuators, and sensors, to provide mechanical stability, adjust alignment, and minimize vibration-induced wear.

русский

русский Español

Español